The Fuji flange transmitter is composed of a remote sealing device added to the ordinary transmitter. The remote sealing device consists of three parts: the flanged diaphragm, the capillary and the filling liquid in the capillary. When working, the measured medium acts on the isolation diaphragm of the flange diaphragm, and the pressure is transmitted to the sensitive element of the transmitter through the filling liquid in the capillary. After conversion, the instrument outputs the corresponding signal.

Fuji double-flange transmitter divides the filling liquid in the capillary into 10 types according to the different requirements of use (see the 13th digit of the selection code for details), and these 10 kinds of filling liquids affect the transmitter's effect on the The operating ambient temperature, process temperature and static pressure lower limit have different requirements. For details, please refer to the following table:

Ambient temperature requirements:

-20°C to 80°C, (for LCD digital display)

-40℃ to 60℃, (for built-in arrester)

-10°C to 85°C, (for "H, S, K" selection codes in silicone oil filling fluid)

+20°C to 85°C, (for "J, T" selection codes in silicone oil filling fluid,)

Process temperature and static pressure lower limit requirements:

|

Filling fluid |

Model code No. 13 |

Process Temperature |

Filling fluid density |

Static pressure lower limit |

Silicone oil |

H |

-15~250℃ |

1.07 |

atmospheric pressure |

|

J |

+85~300℃ |

1.09 |

|

Y |

-40~120℃ |

0.95 |

2.7kPa abs |

|

S |

-15~250℃ |

1.07 |

|

T |

+85~300℃ |

1.09 |

|

K |

-15~200℃ |

1.07 |

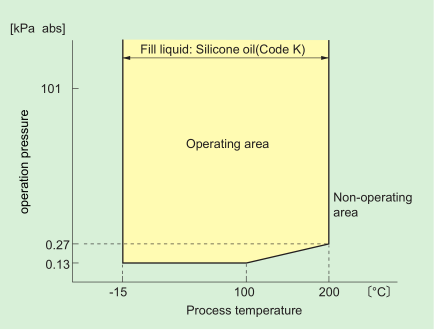

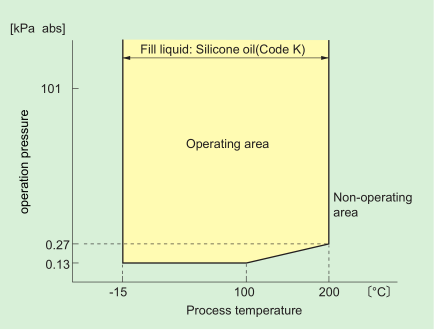

0.13kPa abs |

When using the transmitter whose 13th digit of the selection code is "J, T", the filling liquid is silicone oil with a specific gravity of 1.09. The silicone oil of this specification is very viscous, and the process temperature should be ensured between +85 and 300 °C. The ambient temperature is guaranteed to be between +20 °C and 85 °C, so that the transmitter can work well, so the capillary tube of this specification should be heat traced and insulated. It is recommended to use hot water for heat tracing. After heat tracing and heat preservation, the temperature of the capillary is about 60-80 °C, which should not be too high. Transmitter performance deteriorates.

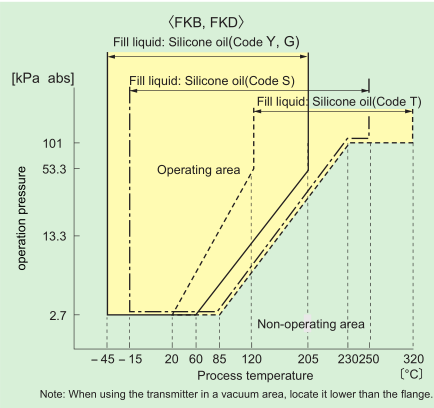

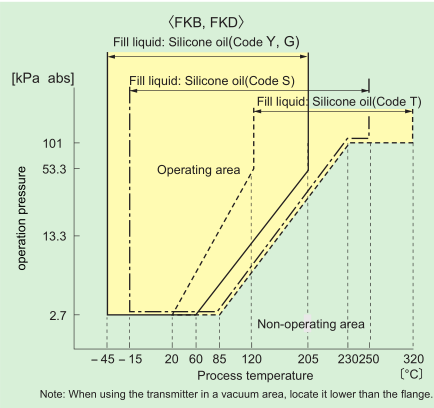

The working temperature and working pressure of the Fuji flange transmitter are interrelated. When the transmitter works under both high temperature and high vacuum conditions, the filling liquid is in a condition that is very easy to vaporize. For this reason, the manufacturer has to carry out special treatment for this kind of transmitter. When the 13th digit is "T" type silicone oil code, the minimum working pressure can reach 2.7kPa abs, and the maximum process temperature can reach 300℃, but these two indicators cannot exist at the same time. The relationship between the specific process temperature and working pressure See table below.

Therefore, when selecting and using a Fuji Double flange transmitter, both operating temperature and operating pressure must be considered.

In order to make the double-flange transmitter for measuring high temperature medium parameters (liquid level, flow rate, etc.) work normally without heat tracing, it is recommended to select H type (working pressure is positive pressure) or K type (working pressure is negative pressure) ) dual flange transmitter with silicone oil, but a heat dissipation section should be added between the pressure valve and the connecting flange of the transmitter to reduce the temperature at the isolation diaphragm of the transmitter to 150 ~ 200 ℃ (in order to ensure that the measured When the medium can flow, the temperature is lower, which can ensure the long life of the transmitter).

When the measured medium is corrosive to 316L, the isolation diaphragm of the Fuji double flange transmitter must choose the corresponding corrosion-resistant material.