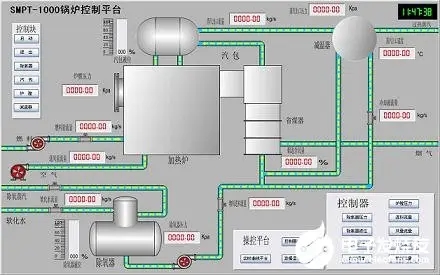

The boiler control system includes: PLC control program, (ignition programmer), and field instruments.

The PLC control program and the ignition programmer complete the control of the ignition process of the boiler. During normal operation, the ignition programmer is only responsible for monitoring and issuing a flameout alarm, and the PLC control program is responsible for all other alarms. The on-site instrument is responsible for detecting various process parameters (pressure, temperature, flow, flame) and transmitting it to the PLC and ignition programmer, which judges whether the boiler is running normally according to the specific situation.

1.1 Ignition programmer

There are three types of ignition programmers in use in boilers:

Mechanical (HONEYWELL R41140L),

Electronic (HONEYWELL BC7000L)

Electronic (HONEYWELL 7800) Their functions are almost the same, the difference is that the latter is a substitute for the former, and the performance is more stable.

1.2 PLC control system

2PLC control is responsible for most of the monitoring functions during normal operation of the boiler. It is the core part of the boiler control system, and its function is realized by the compiled PLC program.

1) PLC chain block

2) Plunger pump start-up block

3) Low atomization pressure alarm block

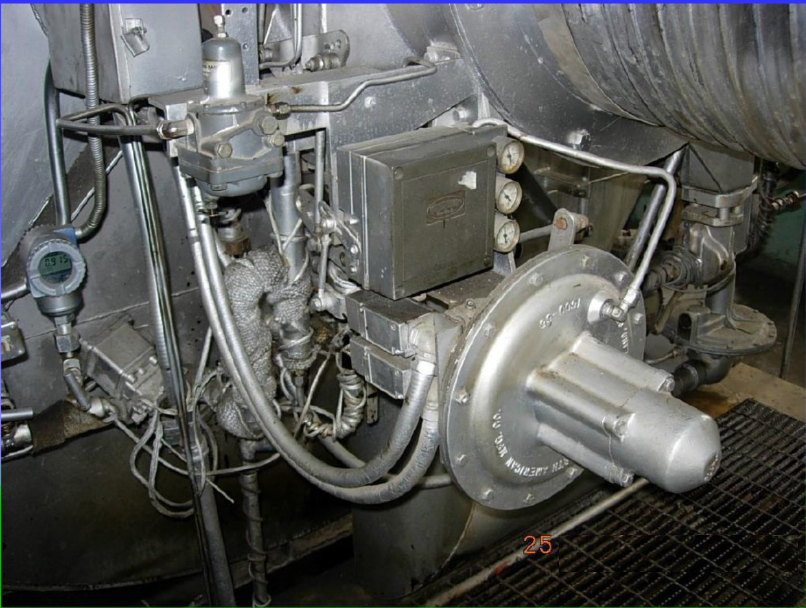

2 Pneumatic control system

Pneumatic control system involves purging solenoid valve, fire regulating solenoid valve, water regulating solenoid valve, water regulating value device, fire regulating bias device, return water regulating valve, differential pressure transmitter and valve positioner, etc.

The following products of our company are widely used in the boiler industry, providing stable and reliable data for the boiler PLC field instrument.

Fuji transmitter, Yamatake transmitter, Yokogawa transmitter, Siemens transmitter, Honeywell transmitter

koso positioner, koso lock valve, ytc positioner

Yokogawa flowmeter, Fuji flowmeter, engiwell flowmeter

Fuji Analyzer